Our Upcycling Brand

– reducing CO2 emissions with clinker

We have developed a clinker that is produced exclusively from material that has been discarded in previous production processes. This is clinker raw material that was found between the production of two types in the conveyor systems. In addition, we add finely ground broken clinker as a component of the recipe. We also filter ceramic raw material from the water cycle in our in-house water treatment facility, which is also used in the upcycling firing process.

This use of 100% secondary material makes appropriate use of our valuable raw material and conserves natural resources. And this has a direct impact on the climate score of your building. With upcycled clinker, you save 25% CO2 compared to a façade made of conventional clinker products – as verified by the official EPD of the Institute for Construction and Environment e.V.

Appreciation of raw materials

Once the clay mixture has been prepared to the point where it can be formed into clinker bricks, it passes through an extruder, which compresses the material.

When production switches to a different colour, the different clays mix together in the extruder.

This creates a mixture of colours that in the past could no longer be used for regular production. The raw materials used to produce our Upcyclingbrand clinker bricks are precisely those that would previously have ended up as waste. This not only makes good use of nature's valuable resources, it also eliminates the need for additional transport, e.g. to extract fresh clay from pits.

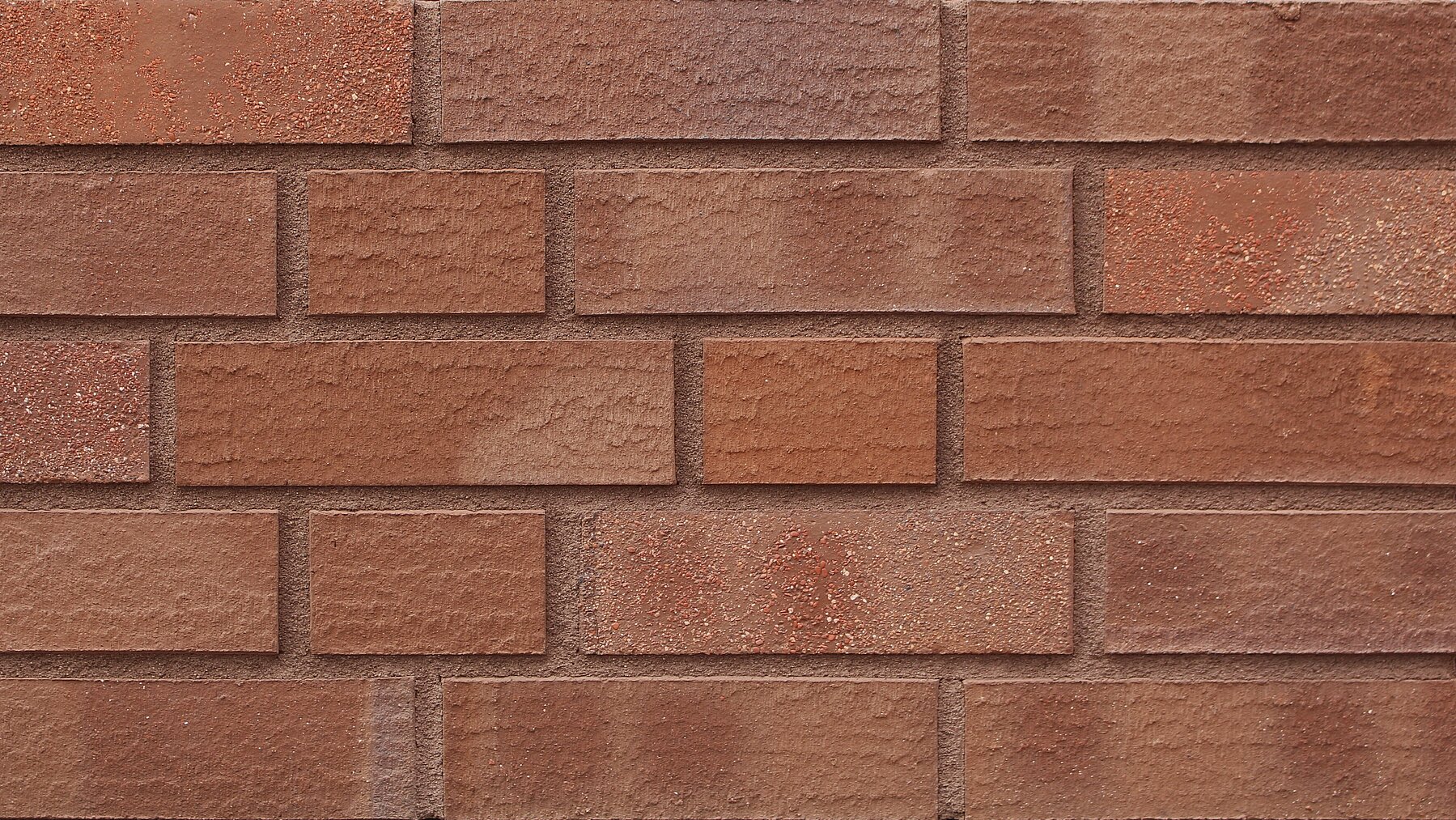

What was long considered a disadvantage, namely the uneven colouring of the clay mixture, is now the great strength of Upcyclingbrand clinker bricks.

Uncompromising

clinker quality

We have developed a number of tests and analyses that enable us to create a processing formulation especially for each edition of our Upcycling Brand to produce a high-quality and durable brick – with no compromise whatsoever.

We can also take a material sample and fire this as a prior test to gain a reference as to the future colour of the final brick, the ‘natural colour’. As always, other parameters such as the format, surface texture and holes of the finished brick are individually coordinated with the customer. In terms of both its production and appearance, our Upcycling Brand is truly unique – just like the people who choose to support a greener future by using such a material.

Own product EPD

with proven CO2 advantage

An EPD for the upcycling brand clinker is available in the database of the Institute for Construction and Environment. The EPD describes and evaluates the upcycling process. The EPD shows a carbon footprint of 141 kg CO2 per tonne of clinker material for upcycled clinker products. Compared to concrete blocks (regularly > 200 kg CO2 / t) or clinker bricks made from conventionally sourced raw materials, this is a CO2 footprint that is up to 30% lower.

Are you looking for accurate and verified data on our Upcyclingbrand clinker bricks for the eco-scoring of your project?

Click here for the complete Download.

Additional commitment

- in the amount of CO2 emissions

With every production batch of Upcyclingbrand, Hagemeister is committed to environmental protection projects in order to offset the CO2 emitted during the production process elsewhere. To this end, we work together with our renowned partner Myclimate. Myclimate supports climate protection projects in developing and emerging countries. The projects meet the highest standards (Gold Standard, Plan Vivo and VCS) and contribute to the UN's Sustainable Development Goals.

Every brand is unique

– and you can help design it!

The basic recipe for Upcyclingbrand Klinker is always the discarded material from previous production processes. This means that the composition of the upcycled raw material varies from batch to batch, resulting in slight, unique colour variations in the base material each time.

However, we offer you many design options for your personal batch: in addition to the format, you can also determine the surface structure. In addition, individual sands or engobes can further change the appearance. The addition of coal during firing can also sharpen the character of the clinker.

Our upcycled clinker bricks are truly unique in their manufacture and appearance – just like the people who choose to use such materials for a greener future.